What is Glitter?

The Introduction Of Glitter

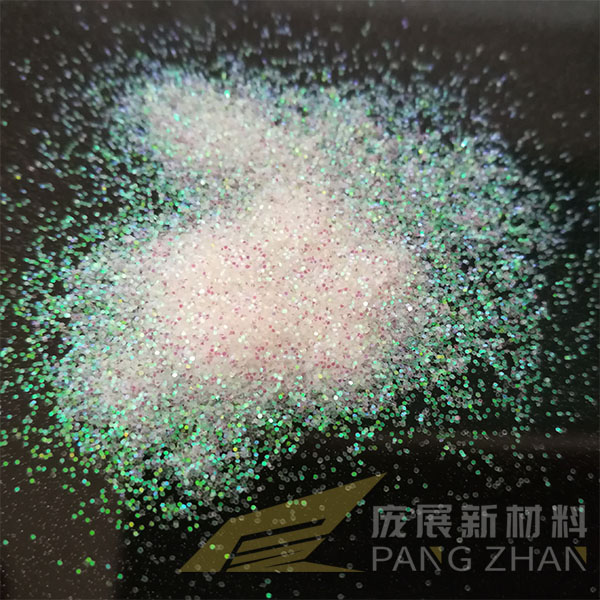

Glitter powder,also known as glitter flake,which is precision cut by the high brightness of different thickness of electroplating film.The material of glitter has PET、PVC,metal aluminum,laser materialsand environmental protection PET material.Glitter powder's particle size can be 0.004mm to 3.0mm,its shape has square,hexagonal,strip shape,currently the common shape of glitter is hexagonal glitter powder.Its metal colors are gold,silver,red,green,purple,blue, copper,black and so on.There are also special rainbow effects,such as iridescent glitter,multi-color glitter,laser silver glitter,laser gold glitter and other laser color glitter.Due to all of our color glitter are added to the surface protective layer,it has bright color and has a certain resistance to climate,temperature and mild corrosive.

The classification of glitter powder's shape and size:

1.Glitter Shape:In the early time,the popular used glitter is square glitter and now the hexagonal glitter powder has been widely used in every industry.Moreover,long strip shape glitter,star glitter,moon glitter,heart glitter,snow glitter and other special shape glitter have been welcomed in the glitter market.

2.The size of hexagonal glitter is divided into 1/500"(the smallest particle size is 0.05 mm)~1/4"(the thickest particle size is 6.0 mm) etc.The glitter size of 1/128"(particle size is about 0.2 mm) is the most common used size.

3.Color and classification:it mainly includes metallic color series(gold,silver,red,blue,green, purple,bronze,etc);rainbow color series (white,red,yellow,blue,green,purple,pink,etc); laser color series

(gold,silver,red,blue,green,purple,bronze etc);special glitter colors also can be customized according to customer requirements.

Glitter Powder Production

The whole production process of glitter powder is divided into five processes:electroplating,high temperature coating printing,film cutting,glitter powder cutting,glitter powder sieving and so on.The final process is weighing glitter,packing glitter and delivery glitter.The core process of glitter quality is high temperature coating printing,which will determine glitters'brightness,high temperature resistance and solvent resistance.

The production standard of glitter

In the glitter market,there are many kinds,colors and specifications of high quality of glitter powder,which are reflected in the following indexes:

1 High brightness: Discriminate the surface brightness of glitter powder.Premium glitter powder has the high brightness and obvious mirror effect is obvious.

2.Shape: Premium glitter powder will have the standard hexagonal glitter shape,which hasn’t obviously different size and powder impurities under the microscope.High quality of glitters will bring you feel smooth.

3.Strong acid and alkali resistance: Premium glitter keep bright color for a long time while soaked in the strong acid and strong alkali liquid.

4.High temperature resistance: Glitter Powder can be cooked and have a resistance to the high temperature.The premium glitter powder won't fade its color after the high temperature cooking.This identification method is mostly used in the of glitter glue pen and glitter nail polish.

Contact Us

Name: June

Tel: +86-0754-86368808

E-mail: [email protected]

Add: Building 4, Time Elite, Hi-tech Development Industrial Zone, Shantou City, Guangdong Province, China

Mail inquiry

Mail inquiry